|

| |

|

Circuit breakers |

|

Definition:

Circuit breaker:- A manually (or remote) operated device capable of making, current-carrying and breaking

currents under normal circuit conditions and also automatically breaks a

circuit under specified abnormal

conditions such as overload and short circuit currents

Definition:

Circuit breaker:- A mechanical switching device capable of

protecting the circuit wiring, capable of making, carrying and breaking

currents under normal circuit conditions and also making, carrying for a

specified time and breaking currents under specified abnormal circuit

conditions such as those of short circuit (IEC 947-1).

|

|

Acronyms:

| SCPD |

Short-Circuit Protective Device |

| CB |

|

| MCB |

Miniature circuit breaker - 0.5 o 125Amp, |

| MCCB |

A circuit breaker having a supporting housing of moulded

insulating material forming an

integral part of the circuit breaker (IEC 947-2). |

| ACB |

Air circuit breaker |

|

|

| In depth look at the

tripping curve:

---------===========---------

Figure

4 – Ground-fault Characteristic Curve

-----------==========-------- |

|

|

Definitions and explanations:

In= Nominal trip current indicated on CB.

|

|

Interrupting

short-circuit current:-

As an example, let us consider a quick acting, current limiting circuit

breaker a

described previously.

To limit the short-circuit current already at its initiation, the main

contacts must

be opened by the striker within a few milliseconds. A very fast acting

device

may need less than 1ms for this. An arc is struck immediately, which driven

towards the arc chamber, delivers a high arc voltage. As a simplification,

the ar

voltage can be considered as an equivalent additional resistance connected

in

series to the current circuit which immediately limits the rising

short-circuit

current.

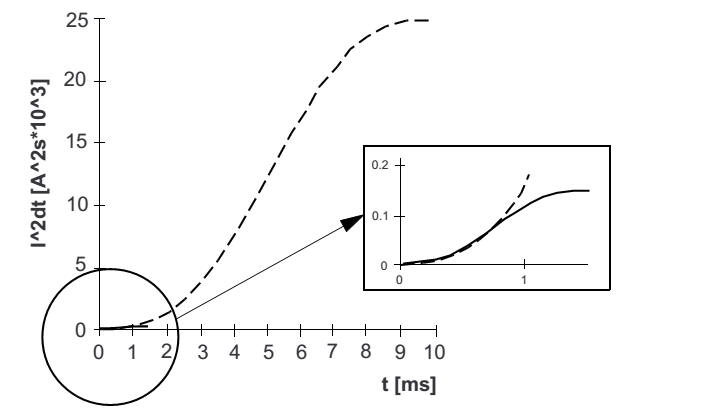

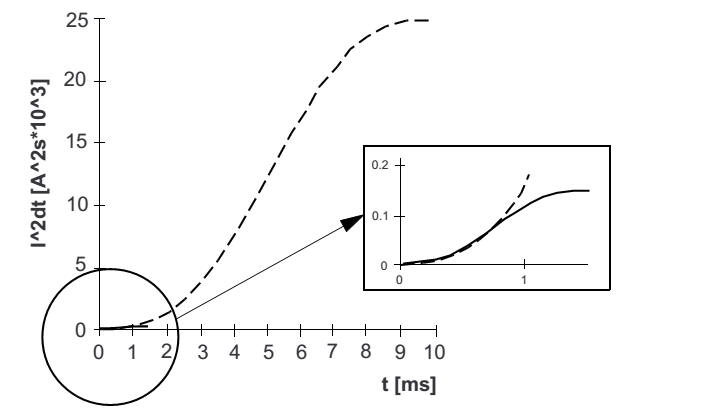

Let-through energy (Joule integral)

of the fast acting circuit breaker 140M

The energy of the short-circuit current integrated over a time period, also

called

the let-through energy I2t (Joule integral), indicates how the components

installed downstream of the circuit breaker, especially switching devices

like a contactor, are less stressed when protected by a current limiting

circuit breaker instead of a current-zero interrupting type.

Note : Although popularly called the let-through energy, the

Joule-Integral gives

only an indication of the let-through energy and do not have the dimension

of

energy. The Joule-Integral multiplied the resistance of the current path is

actu

ally the let-through energy.

The resulting low let-through values of the current limiting circuit

breaker cause

no or very little damage to the components or devices installed downstream

of

the circuit breaker. With the right choice of the various components,

strongly

welded contacts of contactors or severe damage to the connecting wiring or

bus

bars due to uncontrolled arcing can be prevented.

---------------=============------------- Motor protection circuit

breakers:- Adjustable, current dependant

time-delayed overcurrent release protects against thermal overloading.

The ambient air temperature compensation and a precise calibration of the

overcurrent release mechanism assures an exact and reliable tripping. Often

a differential release for the protection against the loss of a phase is

integrated in the device. After the interruption of a short-circuit, the

tripping characteristic must not alter without any outwardly visible

indication.

Fig. 1.4-3: Tripping

curve of a circuit breaker with motor protective characteristics. The

grey line indicates the current form of a normal motor. After the rated

speed is reached (here after about 1.5s), the starting current (6 x In)

reduces to the rated current of the motor(1xIn).

a) Time-current characteristic of the bimetallic release

b) Time-current characteristic of the magnetic release

c) Characteristic of the motor |

|

|

Current limiting circuit breaker

Interrupting

short-circuit current:-

As an example, let us consider a quick acting, current limiting circuit

breaker a

described previously.

To limit the short-circuit current already at its initiation, the main

contacts must

be opened by the striker within a few milliseconds. A very fast acting

device

may need less than 1ms for this. An arc is struck immediately, which driven

towards the arc chamber, delivers a high arc voltage. As a simplification,

the arc

voltage can be considered as an equivalent additional resistance connected

in

series to the current circuit which immediately limits the rising

short-circuit

current.

Let-through energy (Joule integral)

of the fast acting circuit breaker 140M

The energy of the short-circuit current integrated over a time period, also

called

the let-through energy I2t (Joule integral), indicates how the components

installed downstream of the circuit breaker, especially switching devices

like a contactor, are less stressed when protected by a current limiting

circuit breaker instead of a current-zero interrupting type.

Note : Although popularly called the let-through energy, the

Joule-Integral gives

only an indication of the let-through energy and do not have the dimension

of

energy. The Joule-Integral multiplied the resistance of the current path is

actually the let-through energy.

The resulting low let-through values of the current limiting circuit

breaker cause

no or very little damage to the components or devices installed downstream

of

the circuit breaker. With the right choice of the various components,

strongly

welded contacts of contactors or severe damage to the connecting wiring or

bus

bars due to uncontrolled arcing can be prevented. |

Other special characteristics circuit breakers:

- Current-zero interrupting type:-

- Current limiting type:-Interrupt the current during the

initiation of the short-circuit, before the full prospective value can be

attained.

1.2.2.2. Current-zero interrupting type of circuit breaker (“Basics of Circuit breakers - thanks to : http://electrical-engineering-portal.com/download-center/electrical-software/selection-of-mccb-elcb-for-main-branch-circuit 1.2.2.3. Special features of the current limiting circuit breaker In order to reduce the mechanical (due to electro-dynamic forces) and thermal stresses on the object to be protected, the current must be interrupted right during the initiation of the short-circuit, before the full prospective value can be attained (as for example to avoid the welding of the contactor contacts). This is achieved by : • Quick opening of the main contacts. • Rapid build-up of a high arc-voltage (move the arc quickly away from the contact tips and guide it to the arc chamber). The effects of the reduced let-through values are : • Reduction of the electro-dynamic forces on the bus-bars (as for example increased spacing between supports). • Reduction of thermal stresses. The welding of the contacts of contactors can be prevented. Over-dimensioning of the contactors can be avoided or at least kept within reasons. The result is reflected in the short-circuit co-ordination tables - compact starter combinations with components selected mostly on the basis of their rated currents. The current limiting circuit breakers are used in a wide field of applications. It is no longer necessary to carry out complex calculations of the short-circuit current at each point of the network where a circuit breaker is installed. The subject of short-circuit co-ordination takes about as much planning effort as in the case of fuses. The circuit breaker should be constructed in such a way that it can interrupt the short-circuit current under all possible situations without any problem whatsoever. The features, which make the planning with circuit breakers as simple as that with fuses, are : • High breaking capacity makes calculation of short-circuit current superflu- ous: in actual applications, the fault level (prospective short-circuit current) at the point where circuit breakers for motor branch circuits are installed lie mostly in the range of 1…20kA. If the breaking capacity of the circuit breaker is higher than this, no further calculation is necessary. The circuit breakers can be utilised in any point of the installation without calculations for its dimensioning, similar to a high rupturing capacity fuse. • Low let-through values: the contactors connected downstream are less stressed as the short circuit current is appreciably limited by the circuit breakers. Short-circuit co-ordination is simplified and it is not necessary to consult the short-circuit co-ordination tables (the manufacturers perform tests for the short-circuit co-ordination and supply tables in accordance with the IEC 947-4-1 for, as for example, types "1" or "2"). The combination of a circuit breaker and a contactor, both selected on the basis of their rated cur- rents, can in most of the cases fulfil the requirements of the type of co-ordi- nation "2", without any other considerations.

|

|

1.2.2.2. Current-zero interrupting

type of circuit breaker (“Basics of Circuit breakers -

thanks to :

http://electrical-engineering-portal.com/download-center/electrical-software/selection-of-mccb-elcb-for-main-branch-circuit

1.2.2.3. Special features of

the current limiting circuit breaker

In order to reduce the

mechanical (due to electro-dynamic forces) and thermal

stresses on the object to be

protected, the current must be interrupted right during

the initiation of the

short-circuit, before the full prospective value can be attained

(as for example to avoid the

welding of the contactor contacts).

This is achieved by :

•

Quick opening of the main

contacts.

•

Rapid build-up of a high

arc-voltage (move the arc quickly away from the

contact tips and guide it to

the arc chamber).

The effects of the reduced

let-through values are :

•

Reduction of the

electro-dynamic forces on the bus-bars (as for example

increased spacing between

supports).

•

Reduction of thermal stresses.

The welding of the contacts of contactors can

be prevented. Over-dimensioning

of the contactors can be avoided or at least

kept within reasons. The result

is reflected in the short-circuit co-ordination

tables - compact starter

combinations with components selected mostly on

the basis of their rated

currents.

The current limiting circuit

breakers are used in a wide field of applications. It is

no longer necessary to carry

out complex calculations of the short-circuit current

at each point of the network

where a circuit breaker is installed. The subject of

short-circuit co-ordination

takes about as much planning effort as in the case of

fuses.

The circuit breaker should be

constructed in such a way that it can interrupt the

short-circuit current under all

possible situations without any problem whatsoever.

The features, which make the

planning with circuit breakers as simple as that

with fuses, are :

•

High breaking capacity makes

calculation of short-circuit current superflu-

ous: in actual applications,

the fault level (prospective short-circuit current)

at the point where circuit

breakers for motor branch circuits are installed lie

mostly in the range of 1…20kA.

If the breaking capacity of the circuit

breaker is higher than this, no

further calculation is necessary. The circuit

breakers can be utilised in any

point of the installation without calculations

for its dimensioning, similar

to a high rupturing capacity fuse.

•

Low let-through values: the

contactors connected downstream are less

stressed as the short circuit

current is appreciably limited by the circuit

breakers. Short-circuit

co-ordination is simplified and it is not necessary to

consult the short-circuit

co-ordination tables (the manufacturers perform

tests for the short-circuit

co-ordination and supply tables in accordance with

the IEC 947-4-1 for, as for

example, types "1" or "2"). The combination of a

circuit breaker and a

contactor, both selected on the basis of their rated cur-

rents, can in most of the cases

fulfil the requirements of the type of co-ordi-

nation "2", without any other

considerations.

-----------===========-----------

|

| |

|

Types:

Thermal and or magnetic:

Hydraulic magnetic:

|

| |

|

|

Tripping curves:

Other special characteristics circuit breakers:

- Current-zero interrupting type:-

- Current limiting type:-Interrupt the current during the

initiation of the short-circuit, before the full prospective value can be

attained.

|

|

|

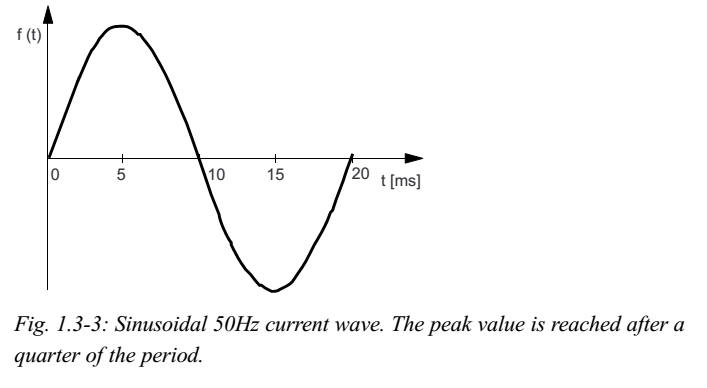

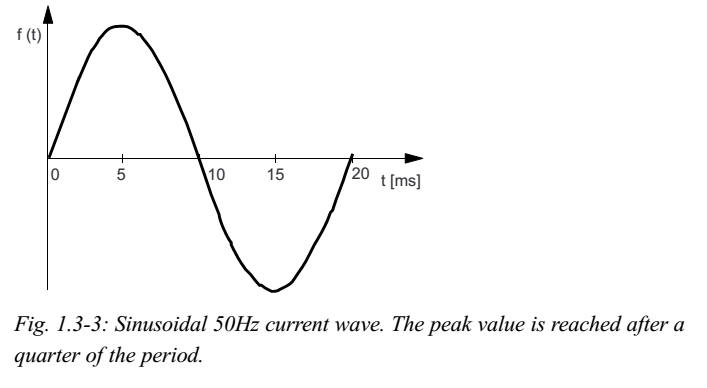

Summary: circuit breaker as load break switch

Analysis of a short circuit:-

The short-circuit current reaches its peak value

after a quarter of the sinusoidal period, which is 5 milliseconds for 50Hz

supply (4.2ms in the case of 60Hz as in the USA), assuming that the current is

symmetrical, i.e. initiated at a current zero. This is to be prevented.

|

|

|

|

|

| |

|

How shall a circuit

breaker be rated:

| SANS.5.2 |

NEC |

SANS |

|

|

| |

|

|

|

|

|

|

An interesting note I found in NEC article 100 definitions: was that the automatic means does

not have to be an integral part of the circuit breaker - that is a

surprise.gs |

For a circuit breaker it must, at a specific voltage

(considering the circuit power factor) and the fault current

equalling its rated breaking capacity or lower be capable of breaking

the circuit. gs

Strange we don't find the "make" anywhere? gs

5.1.3 - EFP

5.2.5 - protection

equipment

7.13 hiV apparatus

2.2.1 South African standards

SANS 152 (SABS 152), Low-voltage air-break switches, air-break

disconnectors, air-break switch-disconnectors

SANS 156 (SABS 156), Moulded-case circuit-breakers.

SANS 556-1, Low-voltage switchgear – Part 1: Circuit-breakers.

SANS 767-1 (SABS 767-1), Earth leakage protection units – Part 1: Fixed

earth leakage protection circuit-breakers.

SANS 61008-1/IEC 61008-1, Residual current operated circuit-breakers

without integral overcurrent protection for household and similar uses (RCCBs)

– Part 1: General rules.

UL 508, Industrial control equipment. check his out in SANS 3.71

short-circuit protective device

SCPD device intended to protect a circuit or p

A

|

|

|

|

How is it

selected for overload current protection

| SANS10142: 6.7.x |

IEC 60364 |

NEC Article 230.42 |

|

6.7 Protection

6.7.1 Overcurrent protection

NOTE The term over current protection includes both overload protection

(see 6.7.2) and short-circuit protection (see 6.7.3).

6.7.1.1

Each protective device shall have a rated current that does not exceed

the lowest of the current-carrying

capacities of any of the conductors of the circuit and shall have a

minimum short-circuit rating of 2,5 kA.

6.7.2 Overload protection

6.7.2.1

Overload protection:

The rated current of the overload protective device shall not

exceed the current-carrying capacity of the conductor it protects,

except in the case of circuits in which the presence of overload

protection could create a dangerous situation, such as in circuits for

lifting magnets

BTW: No mention of the component current

ratings?gs

|

4.4.4.1

Reference:- ABB Comparison of

tripping characteristics

for miniature circuit-breakers

For protection against overload, the

protective device must be selected based on the current carrying

capacity

Ib

≤

In ≤

Iz (standard)

Idesign

≤

Icb ≤

Icable (mine)

and

I2

≤

1.45 x Iz (standard)

Ioperation

≤

1.45 x Icable (mine)

Ib= Design current of a circuit

In= Rated current of the protective

device

Iz= Current carrying capacity of the

cable in accordance with IEC/HD 60364-5-52

I2 = Current ensuring effective

operation in the conventional time of the protective device

IEC 60364-4-43h

|

Where a feeder supplies continuous loads or any combination of

continuous and noncontinuous loads, the rating of the

overcurrent device shall not be less than the noncontinuous load plus

125% of the continuous load.

Exception: Where the assembly including the overcurrent

devices protecting the feeder(s) are

listed for operation at 100% of their rating, neither the ampere rating

of the overcurrent device nor the ampacity of the feeder conductors

shall be less than the sum of the continuous load plus the noncontinuous

load.

Only breakers listed for 100% application,

and so labelled can be applied under the exception (for example loads

Frame and R Frame 140G’s that are specifically marked and rated 100%).

Breakers without a 100% application listing and label are

applied at 80% of rating

I could not find this in the NEC 2011

this is in 2011:II. Branch-Circuit Ratings

210.19 Conductors — Minimum Ampacity and Size.

(A) Branch Circuits Not More Than 600 Volts.

(1) General. Branch-circuit conductors shall have an ampacity not less

than the maximum load to be served. Where a branch circuit supplies

continuous loads or any combination of continuous and noncontinuous

loads, the minimum branch-circuit conductor size, before the application

of any adjustment or correction factors, shall have an allowable

ampacity not less than the noncontinuous load plus 125 percent of the

continuous load.

Exception: If the assembly, including the overcurrent devices protecting

the branch circuit(s),

is listed for operation at 100 percent of its

rating, the allowable ampacity of the branch circuit conductors

shall be permitted to be not less than the sum of the continuous load

plus the noncontinuous load.

Informational Note No. 1: See 310.15 for ampacity

ratings

of conductors.

Informational Note No. 2: See Part II of Article 430 for

minimum rating of motor branch-circuit conductors.

Informational Note No. 3: See 310.15(A)(3) for temperature limitation of

conductors. |

|

b) Opening under overload conditions

1) Instantaneous or definite time-delay operation

The release shall cause tripping of the circuit-breaker with

an accuracy of i10 O/. of the tripping current value of the current setting

for all values of current setting of the overload

release.

2) Inverse time-delay operation. Conventional values for

inverse time-delay operation are given in table 6.

|

IEC 60947-2:

7.2.5 Ability to make and break under short-circuit

conditions

Subclause 7.2.5 of Part 1 applies with the following

amplifications:

The rated short-circuit making capacity shall be in

accordance with 4.3.5.1(Rated short circuit making capacity) and

4.3.5.3 (Standard relationship between short-circuit making and breaking

capacities and related power factor, for a.c. circuit-breakers)

The rated short-circuit breaking capacity shall be in

accordance with 4.3.5.2

The rated short-time withstand current shall be in

accordance with 4.3.5.4

NOTE It is the manufacturer’s responsibility to ensure that

the tripping characteristic of the circuit-breaker IS compatible with the capability of the circuit-breaker to withstand the

inherent thermal and electrodynamlc stresses

---============-----

and the association shall comply with the requirements of 7.2.1.2.4, item

a)

-----===========----

7.2.1 .2.4 Opening by over-current releases a)

b)

Opening under short-circuit conditions

The short-circuit release shall cause tripping of the

circuit-breaker with an accuracy of

20% of the tripping current value of the current

setting for all values of the current setting

of the short-circuit current release.

Where necessary for over-current co-ordination (see

2.17), the manufacturer shall provide Information (usually curves)

showing. maximum cut-off (let-through) peak current (see 2.5 19 of Part

1) as a function of prospective current (r, m.s. symmetrical);

— /2t characteristics (see 2.18) for circuit-breakers of

utilization category A and, if applicable, B for circuit-breakers with

instantaneous override (see note to 8.3.5).

Conformity with this information may be checked during

the relevant type tests in test

sequences II and Ill (see 8.3.4 and

8.3.5).

NOTE It may be possible to provide other forms of data

to verify co-ordination characteristics of circuitbreakers, for example,

tests on combinations of short-circuit protective devices.

Opening under overload conditions

1) Instantaneous or definite time-delay operation

The release shall cause tripping of the circuit-breaker

with an accuracy of i10 O/. of

the

tripping current value of the current setting for all

values of current setting of the overload release.

2) Inverse time-delay operation Conventional values for

inverse time-delay operation are given in table 6.

At the reference temperature (see 4.7.3) and at 1,05

times the current setting (see 2.4.37

of Part 1), i.e. with the conventional non-tripping

current (see 2.5.30 of Part 1), the opening

release being energized on all phase poles, tripping

shall not occur in less than the

conventional time (see 2.5.30 of Part 1) from the cold

state, i.e. with the circuit-breaker at the reference temperature.

Moreover, when at the end of the conventional time the

value of current is immediately raised to 1,30 times the current

setting, i.e. with the conventional tripping current (see 2.5.31 of Part

1), tripping shall then occur in less than the conventional time later.

NOTE The reference temperature is the ambient air

temperature on which the time-current characteristic of the

circuit-breaker is based. 4.7.3

Table 6

simply says

for

lower/equal to 63Amps - at 1.05In circuit must trip after 1 hr only, if

then raised to 1.3In it must trip ONLY within 1hr

at bigger

then 63amps it becomes 2hr

They talk

about this time as conventional time. |

|

| |

DEFINING THE TRIPPING CURVE

4.7.4 Tripping time

setting of over-current releases

1) Definite time-delay over-current releases

The time-delay of such releases is independent of the over-current.

The

tripping time setting shall be stated as the duration in seconds of the

opening time of the circuit-breaker, if the time-delay is not

adjustable, or the extreme values of the opening time~ if the time delay

is adjustable.

2) Inverse time-delay over-current releases

The time-delay of such releases is dependent on the over-current.

The time/current characteristics shall be given in the form of curves

supplied by the

manufacturer.

These shall indicate how the opening time, starting from

the cold state, varies with current within the range of operation of the

release.

The manufacturer shall indicate, by suitable means,

the tolerances applicable to these curves.

These curves shall be given for each extreme value of

the current setting and, if the time

setting for a given current setting is adjustable, it is recommended

that they be given in

addition for each extreme value of the time setting.

NOTE It is recommended that the current be plotted as

abscissa and the time as ordinate, using logarithmic scales.

Furthermore, in order to facilitate the study of

co-ordination of different types of over-current protection,

!t is

recommended that the current be plotted as multiples of the setting

current and the time in seconds on the standard graph sheets detailed in

5.6.1 of IEC 60269-1 and in figures 4(l), 3(11) and 4(11) of IEC

60269-2-1. |

|

| |

Circuit breaker

Reference temperature: lS/lEC 60947-2:2003

Unless otherwise specified – the operating value of

overload releases other than those of the thermal type is independent of

the ambient air temperature within the limits of -5 “C to +40 ‘C;

for releases of the thermal type, the values stated are

for a reference temperature of +30 “C i 2 “C. The manufacturer shall be

prepared to state the influence of variations in the ambient air

temperature (see 7.2.1.2.4, item b)).

|

|

| |

|

|

And short circuit currents:

| SANS10142: 6.7.3 |

|

|

Short-circuit protection

6.7.3.1 At its point of installation, a short-circuit protective device

shall be capable of breaking any over current up to the value of the

prospective short-circuit current. (See also 6.7.4 on cascaded systems.)

|

|

|

|

| And the impedance?

| BS EN 60947-2 - calculating Zs |

|

|

In this case Zs is determined from the basic equation:-

Zs Ia≤ UoCmin– which transposes to: - Zs≤ ((UoCmin)/Ia) where:-

Uo is the nominal voltage to earth.

Ia is the current required to achieve the disconnection time as given in

the Regulations.

Cmin is the minimum voltage factor to take account of voltage

variations depending on time and place, changing of transformer taps and

other considerations.

NOTE: For a low voltage supply given in accordance with the

Electricity Safety, Quality and Continuity. Regulations 2002 as amended,

Cmin is given the value 0.95.

|

|

|

|

| |

| |

|

|

|

|

What does the

standards say about Prospective fault current?

| SANS 10142 |

IEC |

|

6.6.1.15 Switchgear shall be fully rated

for withstanding the prospective

short-circuit current that could occur at that point in the system,

unless

series-connected (cascaded)

systems are applied in accordance with

6.7.4.6.6.1.16 Where the prospective fault

level of the supply cannot be determined, a fault current meter may be

used (see 8.5.2).

6.6.1.17 All

disconnecting devices in a distribution board

a) shall be protected by a fully rated short-circuit protective device,

and

b) when used in combination with a short-circuit protective device (see

6.7.4), shall have a conditional

short-circuit current rating (see 3.22.1)

appropriate to its condition of installation, but of not less than 2,5

kA

|

|

|

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

| |

IEC 60947.2: 4.4: Utilisation categories |

|

| |

Table 4- Utilization categories

Category ACircuit-breakers not

specifically intended for selectivity under short-circuit conditions with respect to other short-circuit

protective devices in series on the load side, i.e. without an intentional

short-time delay provided for selectivity under short-circuit conditions,

and therefore without a short-time withstand current rating according to 4.3.5.4.

Category B

Circuit-breakers specifically intended for selectivity

under short-circuit conditions with respect to other short-circuit

protective devices in series on the load side, i.e. with an intentional short-time

delay (which may be B adjustable), provided for selectivity under

short-circuit conditions. Such circuit-breakers have a short-time withstand current

rating according to 4.3.5.4.

NOTE Selectivity is not necessarily ensured up to the

ultimate shortcircuit breaking capacity of the circuit-breakers (for example

in the case of operation of an instantaneous release) but at least up to the

value specified in table 3.

table 11 (see 8.3.2.2.4 and 8,3.2,2.5),

NOTE 2 Attention is drawn to the different requirements

for the minimum required percentage of lc~ for utilization categories A and B, in accordance with table

1.

NOTE 3 A circuit-breaker of utilization category A may

have an intentional short-time delay provided for selectivity under conditions other than those of short

circuit, with a short-time withstand current less than that according to table 3. In that case, the tests include test sequence

IV (see 8.3.6) at the assigned short-time

|

|

|

| Hager |

|

|

| •Ref:Electricians handbook courtesy of

Larson and Toubro - India:

IEC classifies MCBs into three category depending upon their “Quality

of current

limiting” & let through energy of a circuit breaker on short circuits.

Permissible let to energy values for circuit breakers with rated current

up to end including 16A as per

EN60898 are:

Class 1 No limitation

Class 2 290 kA²S

Class 3 84 kA²S -

*All Hager mcb are class 3

|

|

|

|

|

Where must it be installed?

| south Africa

SANS10142: 6.7.1.1 |

Europe + IEC 60364

|

USA+ UL489

UL1077

|

Canada

CSA c22.2 No 5.02CSA c22.2 No 235-04

|

|

china GB 14048-2 |

| 6.7.2.2 Overload must be installed at point of conductor

reduction OR - with a switch/disconnector OR earth-leakage unit that

requires overload protection. UNLESS

The over current device can sit anywhere in the cable as long as no

connections to/from it

AND

entire length protected against shorts circuit OR

cable shorter then 5mtrs

not near flammable materials

not likely to cause humans harm

I spent a lot of time trying to get

to grips with this - I get this feeling this commission could not get

consensus the matter of "anywhere in the cable"...thus the strange

additions. Flammable and human safety? Really?

Now the challenge: Overload unit

can be anywhere in the cable but the whole cable must be short circuit

protected? HOW?

Mechanical protection or another

electrical component? Are

we confusing motor overload protection with cable / reticulation

protection here? |

G-2 CASES WHERE SHORT-CIRCUIT PROTECTION DOES NOT

NEED TO BE PLACED AT THE ORIGIN OF BRANCH CIRCUIT With

reference to 4.4.5.2.1and Fig. G.1, short-circuit protective device P

2may be moved up to 3 m from the origin (O) of the branch circuit (S2)

provided that there is no other connection or socket-outlet on this

length of the branch circuit, and in the case of 4.4.5.2.1

the risk of short-circuit, fire and danger to persons is reduced to a

minimum for this length.

but:

4.4.4.2 Position of devices for overload protection

4.4.4.2.1 A device ensuring protection against overload shall be placed

at the point where a

change, such as a change in cross-sectional area, nature, method of

installation or in constitution,

causes a reduction in the value of current-carrying capacity of the

conductors, except where

4.4.3.2.2and 4.4.3.3 apply.

4.4.4.2.2 The device protecting the conductor against

overload may be placed along the run of that conductor if the part of

the run between the point where a change occurs (in cross-sectional

area, nature, method of installation or constitution) and the position

of the protective device has neither branch circuits nor socket-outlet

circuits and fulfils at least one of the following two conditions:

a) it is protected against short-circuit current in accordance with the

requirements stated in 4.4.5;

b) its length does not exceed 3 m, it is carried out

in such a manner as to reduce the risk of shortcircuit to

a minimum, and it is installed in such a manner as to reduce to a

minimum the risk of

fire or danger to persons (see also 4.4.5.2.1).

NOTE: For installation according to a) see Figure F.1.

For installation according to b) see Figure F.2. |

|

|

|

|

| |

|

|

|

|

|

| 6.7.2.3The overload protective device

may be installed at any point in the conductor run that it protects,

provided that

a) there is no branch circuit or socket-outlet between

the point where there is a reduction in the conductor's current-carrying

capacity and the point where the device is installed, and

b) the entire length of the conductor is protected against

short-circuit, or

c) the conductor is

1) of length not exceeding 5 m,

2) so installed as to minimize the risk of overload or fault in its

operating condition,

3) not near flammable materials, and

4) not likely to cause harm to a person in the event of a fault |

|

|

|

|

|

| Now short circuit protection is as plain

and simple as "installed at the point of reduction" - as it should be!

6.7.3.2 |

AND SHORT CIRCUITS?

4.4.5.2 Position of devices for short-circuit

protection A device ensuring protection against short-circuit shall

be placed at the point where a reduction in the cross-sectional area of

the conductors or another change causes a change to the current-carrying

capacity of the conductors, except where 4.4.5.2.1, 4.4.5.2.2or 4.4.5.3

applies.

4.4.5.2.1 The various cases stated in the following sub clause shall not

be applied to installations situated in locations presenting a fire risk

or risk of explosion and where special rules for certain

locations specify different conditions. The device for protection

against short-circuit may be placed other than as specified in 4.4.4.2,

under the following conditions.

In the part of the conductor between the point of

reduction of cross-sectional area or other change and the position of

the protective device there shall be no branch circuits nor

socket-outlet circuits

and that part of the conductor shall:

a) not exceed 3 m in length, and

b) be installed in such a manner as to reduce the risk of a

short-circuit to a minimum,

and so forth and so forth...

|

|

|

|

|

|

|

... |

| |

|

Omitting fault current protection device

| IEC 60364 |

|

4.4.4.3 Omission of devices for

protection against overload

The various cases stated in this sub-clause shall not be applied to

installations situated in locations

presenting a fire risk or risk of explosion or where the requirements

for special installations and

locations specify different conditions.

4.4.4.3.1 General Devices for protection against

overload need not be provided:

a) for a conductor situated on the load side of a change in

cross-sectional area, nature, method of

installation or in constitution, that is effectively protected against

overload by a protective

device placed on the supply side;

b) for a conductor that is not likely to carry overload current,

provided that this conductor is

protected against short-circuit in accordance with the requirements of

4.4.4 and that it has neither branch circuits nor socket-outlets;

c) at the origin of an installation where the distributor provides an

overload device and agrees that it affords protection to the part of the

installation between the origin an d the main distribution point of the

installation where further overload protection is provided.

d) for circuits for telecommunications, control, signalling and the

like.

NOTE: For installations according to a), b) and d), see Fig. F.3.

|

|

| |

|

| |

|

|

|

Relevant standards and circuit breakers:

PS: This is a reference based on manufacturer material

referring to the different standards - Excuse if you are specialist and find

some discrepancy...just let us know - for this is always a work in progress

we would be a happy to oblige.

| |

UL |

ANSI |

NEC |

CSA |

IEC |

| Genl |

|

|

Articles: 210 - Branch circuits

215 - Feeders

240 - Overcurrent Protection

430 - Motors, Motor Circuits, and Controllers

controllers, and m |

|

|

| MCB |

UL1066 - LV AC and DC CB in Enclosures

|

- ANSI C37.13: IEEE Standard for Low-Voltage AC Power

Circuit Breakers Used in Enclosures

- ANSI C37.16: Low-Voltage Power Circuit Breakers and AC

Power Circuit Protectors.

Preferred Ratings, Related Requirements, and Application

Recommendations

- ANSI C37.17: American National Standard for Trip

Devices for AC and General

Purpose DC Low Voltage Power Circuit Breakers

|

|

|

IEC 60947-2 (circuit breaker design and manufacturing)

IEC 60364, § 434.5.1 (electrical distribution network).

| IEC 947-4 - Circuit breakers with motor

protective characteristics. |

|

| MCCB |

UL 489 - NEC -Branch circuit protection. MCCB. UL 489: Molded-Case

Circuit Breakers, Molded-Case Switches and Circuit

Breaker Enclosures

UL 489 MCCB: MCS(Molded Case Switches) & Circuit Breaker Enclosures.

| UL 489A - Branch circuit protection DC circuit breaker short circuit

protection in communications equipment. |

| UL1077 - Used in conjunction with CB for supplementary external device

protection. |

| Branch circuit protection. |

| UL1077 - Used in conjunction with CB for supplementary external device

protection. |

| |

| UL486- evaluation of lugs connection in field wiring this includes

items under UL489. |

| |

|

|

|

CSA C22.2 No. 5. 5-02 - CEC - Canadian -

CSA C22.2 No.235 - Used in conjunction with CB for supplementary

external device protection. |

|

| ACB |

|

|

|

|

|

|

| |

| |

| |

| Definitions:

|

| |

|

Analysis of a short circuit:-

The short-circuit current reaches its peak value

after a quarter of the sinusoidal period, which is 5 milliseconds for 50Hz

supply (4.2ms in the case of 60Hz as in the USA), assuming that the current is

symmetrical, i.e. initiated at a current zero. This is to be prevented.

bxc |

Coordination/Cascading/Backup protection

And lets dig deeper according to what standards say:

| |

IEC 60947-2.2003

|

|

|

|

| |

he obvious is that the information all provided by

manufacturer and the components comply to relevant standards.

Ultimately: The maximum

conditional short-circuit current (see 2.5.29 of Part 1) shall not

exceed the rated ultimate short-circuit breaking capacity of the SC PD.

IEC 60947.2.2003

A.5 Verification of discrimination

Discrimination can normally be considered by desk study alone, i.e. by

a comparison of the

operating characteristics of C1 and the associated SCPD, for example, when

the associated

SCPD is a circuit-breaker (C2) provided with an intentional time-delay,

The manufacturers of both the C1 and the SCPD shall provide adequate data

concerning the

relevant operating characteristics so as to permit Is to be determined for

each individual

association.

In certain cases, tests at Is are necessary on the association, for

example

— when C1 is of the current-limiting type and C2 is not provided with an

intentional time-delay;

— when the opening time of the SCPD is less than that corresponding to one

half-cycle,

To obtain the desired discrimination when the associated SCPD is a

circuit-breaker, an

intentional short-time delay may be necessary for C2.

Discrimination may be partial (see figure A.4) or total up to the rated

short-circuit breaking

capacity Icu (or Ics) of C1. For total discrimination, the non-tripping

characteristic of C2 or

the pre-arcing characteristic of the fuse shall lie above the tripping

(break-time) characteristic

of C1.

Two illustrations of total discrimination are given in figures A.2 and A.3.

A.6 Verification of back-up protection

A.6.1 Determination of the take-over current: -Compliance with the

requirements of A.3,2 can be checked by comparing the operating

characteristics of Cl and the associated SCPD for ail settings of Cl and, if

applicable, for all

settings of C2.

A.6.2 Verification of back-up protection

a) Verification by tests.

Compliance with the requirements of A.3.3 is normally verified by tests in

accordance with

A.6.3. In this case, all the conditions for the tests shall be as specified

in 8.3.2.6 with the

adjustable resistors and inductors for the short-circuit tests on the supply

side of the

association.

b) Verification by comparison of characteristics

In some practical cases and where the SCPD is a circuit-breaker (see figures

A,4 and A.5),

it may be possible to compare the operating characteristics of Cl and of the

associated

SCPD, special attention being paid to the following:

– the Joule integral value of C1 at its Icu and that of the SCPD at the

prospective current

of association;

– the effects on C1 (e.g. by arc energy, by maximum peak current, cut-off

current) at the

peak operating current of the SCPD.

In some practical cases and where the SCPD is a circuit-breaker (see

figures A,4 and A.5),

it may be possible to compare the operating characteristics of Cl and of the

associated

SCPD, special attention being paid to the following:

– the Joule integral value of Cl at its /CU and that of the SCPD at the

prospective current

of association;

– the effects on Cl (e.g. by arc energy, by maximum peak current, cut-off

current) at the

peak operating current of the SCPD.

The suitability of the association may be evaluated by considering the

maximum total

operating I2t characteristic of the SCPD, over the range from the rated

short-circuit breaking

capacity Icu(or Ics) of C1 up to the prospective short-circuit current of

the application, but not

exceeding the maximum let-through I2t of C1 at its rated short-circuit

breaking capacity or

other lower limiting value stated by the manufacturer.

NOTE Where the associated SCPD is a fuse, the validity of the desk study is

limited up to Icu of

A.6.3 Tests for verification of back-up protection

If C1 is fitted with adjustable over-current opening releases, the operating

characteristics shall

be those corresponding to the minimum time and current settings,

If C1 can be fitted with instantaneous over-current opening releases, the

operating

characteristics to be used shall be those corresponding to Cl fitted with

such releases,

If the associated SCPD is a circuit-breaker (C2) fitted with adjustable

over-current opening

releases, the operating characteristics to be used shall be those

corresponding to the

maximum time and current settings.

If the associated SCPD consists of a set of fuses, each test shall be made

using a new set of

fuses, even if some of the fuses used during a previous test have not blown

Where applicable, the connecting cables shall be included as specified in

8.3.2.6.4 except that,

if the associated SCPD is a circuit-breaker (C2), the full length of cable

(75 cm) associated with

this circuit-breaker may be on the supply side (see figure A.6).

Each test shall consist of a O–t–CO sequence of operations made in

accordance with 8.3.5 of

this standard, ‘whether at /Cu or /C~, the CO operation being made on Cl.

A test is made with the maximum prospective current for the proposed

application, This shall

not exceed the rated conditional short-circuit (see 4.3.6.4 of Part 1),

A further test shall be made at a value of prospective current equal to

the rated short-circuit

breaking capacity /Cu (or /CS) of Cl, for which test a new sample Cl may be

used, and also, if

the associated SCPD is a circuit-breaker, a new sample C2.

a) if the associated SCPD is a circuit-breaker (C2):

– either both Cl and C2 shall trip at both test currents, no further tests

then being

required.

This is the general case and provides back-up protection only.

– or C1 shall trip and C2 shall be in the closed position at the end of each

operation, at

both test currents, no further tests then being required,

This requires that the contacts of C2 separate momentarily during each

operation. In this

case restoration of the supply is provided, in addition to back-up

protection (see note 1 to

figure A.4), The duration of interruption of supply, if any, shall be

recorded during these

tests.

– or C1 shall trip at the lower test current, and both C1 and C2 shall trip

at the higher test

current.

This requires that the contacts of C2 separate momentarily at the lower test

current.

Additional tests shall be made at intermediate currents to determine the

lowest current at

which both C1 and C2 trip, up to which current restoration of supply is

provided. The

duration of interruption of supply, if any, shall be recorded during these

tests.

– or C1 shall trip at the lower test current, and both C1 and C2 shall

trip at the higher test

current.

This requires that the contacts of C2 separate momentarily at the lower test

current.

Additional tests shall be made at intermediate currents to determine the

lowest current at

which both C1 and C2 trip, up to which current restoration of supply is

provided. The

duration of interruption of supply, if any, shall be recorded during these

tests.

b) if the associated SCPD is a fuse (or a set of fuses):

—

In the case of a single-phase circuit at least one fuse shall blow;

— in the case of a multi-phase circuit either two or more fuses shall blow,

or one fuse shall

blow and C1 shall trip.

A.6.4 Results to be obtained

Subclause 8.3.4.1.7 of Part 1 applies.

Following the tests, C1 shall comply with 8.3,5.3 and 8.3.5.4

In addition, if the associated SPCD is a circuit-breaker (C2), it shall be

verified, by manual

operation or other appropriate means, that the contacts of C2 have not

welded.

|

|

|

|

| |

|

|

|

|

...

|

|

Up side down circuit breakers

| SANS 2012 |

NEC |

|

|

6.8.2.3

Circuit-breakers, disconnectors and switch-disconnectors shall not be

mounted upside down.

Who would want to do this anyway...zimzum.

Horizontal mounting is

allowed unless specifically prohibited by the manufacturer.

Any deviation from the convention of connecting line to

the top and load to the bottom of switchgear is not recommended. Reverse

connection is allowed only if

a) it is specifically allowed by the manufacturer,

b) "load" and "line" are so marked that they are clearly

visible during

maintenance, and

c) any contradictory marking is not visible after

installation. |

NEC404.7

inferred so, |

|

|

|

|

|

AC circuit breakers and power factor:

Standard relationship between short-circuit breaking and making

capacities and related power factor.

Table 2 -ratio n between short-circuit making capacity and short-circuit

breaking capacity and related power factor (for a.c. circuit-breakers)

| Short-circuit breaking capacity I kA r.m.s. |

Power factor |

I Minimum value required for n

n=(short - circuit making capacity/short - circuit breaking capacity) |

4,5 <= / <= 6

6 <= / <=10

10 <= / <= 20

20 <= I <= 50

50 <= / |

0,7

0,5

0,3

0,25

0,2 |

1,5

1,7

2,0

2,1

2,2 |

| |

|

|

| |

|

|

| |

|

|

NOTE: For values of breaking capacity lower than 4,5 kA, for certain

applications, see table 11 for the power

factor.

The rated short-circuit making and breaking capacities are only valid

when the circuit-breaker

is operated in accordance with the requirements of 7.2.1,1 and 7.2. i.2.

For special requirements, the manufacturer may assign a value of rated

short-circuit making

capacity higher than that required by table 2. Tests to verify these rated

values shall be the

subject of agreement between manufacturer and user.

|

| |

|

|

|

|

|

|

|

|

|

|

|

MCCB range |

| ABB Tmax - 15 to 3000Amps, |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

ACB (low voltage Power circuit breakers)

| ABB:

Emax: 400 to 5000A

but I saw the SACE can go to 6300A

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

Online references:

http://www.electrical-installation.org/enwiki/Fundamental_characteristics_of_a_circuit-breaker

http://www.electrical-installation.org/enwiki/Fundamental_characteristics_of_a_circuit-breaker

http://www.terasaki.co.uk/tembreak2/application note_mccb.htm

|

| Drawing notations: |

|

|

Standards references:

| EN

60947-2 |

| IEC 947-4 - Circuit breakers with motor

protective characteristics. |

______________==========_____________

| UL 489 - NEC -Branch circuit protection. MCCB. |

| UL 489A - Branch circuit protection DC circuit breaker short circuit

protection in communications equipment. |

| UL1077 - Used in conjunction with CB for supplementary external device

protection. |

| CSA C22.2 No. 5. 5-02 - CEC - Canadian - Branch circuit protection. |

| UL1077 - Used in conjunction with CB for supplementary external device

protection. |

| CSA C22.2 No.235 - Used in conjunction with CB for supplementary

external device protection. |

| UL486- evaluation of lugs connection in field wiring this includes

items under UL489. |

______________==========_____________

VC8035 -

VC8036 -

|

|

| |

| |

| |

|