|

| |

----------------------------=========================------------------------

| |

|

PURPOSE OF EARTHING

In order to avoid the risk of serious electric shock, it is important

to provide a path for earth leakage currents to operate the circuit

protection, and to endeavour to maintain all metalwork at the same

potential. This is achieved by bonding together all metalwork of

electrical and non-electrical systems to earth.

|

EARTHING SYSTEMS

Various excepted methodologies of electrical supply exist around the world

but they all serve one common purpose – The phase (live) supply relationship

to the earth-mass determines how safe we are from electrocution…

| SANS adopted the IEC standards and recommendations. |

IEC IEC 60364 |

|

| In general the South African reticulation is based on TN-S

system |

A peculiar acronym identify

the basic systems.

Seems to be

based on the French lingo.

When these letters are grouped, they form the classification of a type of

system.

The first letter denotes how the supply source is earthed.

The second denotes how the metalwork of an installation is earthed. The

third and fourth indicate the functions of neutral and protective

conductors.

|

The two

+ 1 +1 code |

|

The

First Letter indicates how the Earthing is done on Source side

(Generator / Transformer). |

|

The

Second Letter indicates how the Earthing is done on Device side (place

where electricity is consumed at customer premises). |

| 3rd and sometimes 4th

letters: |

| C - combined

S - separate.

CS - Combined in supply separated in installation: |

T

–

(French word “Terre” meaning Earth) – It means direct connection of a

point to earth

I

– It means that either no point is connected to Earth or it is connected

via high impedance

N

– It means that there is direct connection to neutral at the source of

installation which is in turn connected to the ground

Based on a

combination of these three letters, there are three families of Earthing

arrangements proposed by IEC as below:

|

TN

Network |

|

TT

Network |

|

IT

Network |

| So you can have: |

| There are three sub-types of TN

networks as below:

TN-S

TN-C

TN-C-S

TN-S: In this, separate conductors for Protective Earth (PE) and

Neutral run from Consumer’s electrical installation till the source.

They are connected together only at the power source. |

|

These have been designated in the IEE Regulations using the letters: T, N, C

and S. These letters stand for:

T - Terre (French for earth) and meaning a direct connection to earth.

N - neutral

|

---------============-------

For the UK: BS 7671: 2008 defines or lists the types of system

earthing in

Part 2 – (definitions)

and these are also defined in BS 7430: 1998.

-----------===========---------

PE – Acronym for “Protective Earth” – is the conductor that connects

the exposed metallic parts of the consumer’s electrical installation

to the ground.

|

NB: IT Network

In IT type of earthing system, there is either no connection to earth at

all, or it is done via a high impendence earthing connection.

About “ IT ” :

We should also mention to the following :

1- If the connection of the transformer is “ ∆ ” ( no neutral point ) we

can connect one phase to earth via high impedance.

2- Two main types of “ IT ” that are :

– IT with distributed Neutral

– IT without distributed Neutral.

3- With this Earthing

system, It’s absolutely necessary to use special devices called “

Insulation Monitoring Devices ” to detect and indicate any insulation

fault . |

|

----------==========------------ |

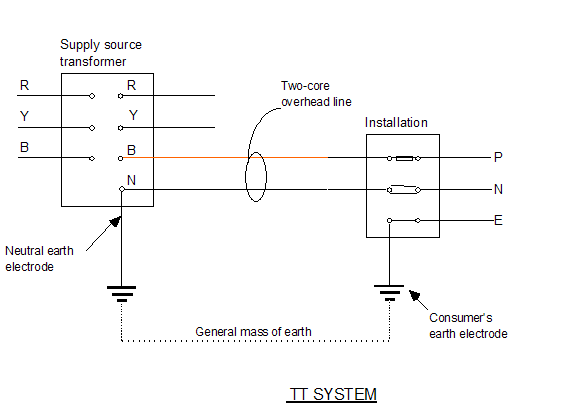

| -------TT SYSTEM------

-----===========-------------

A TT system has a direct connection to the supply source to earth and

a direct connection of the installation metalwork to earth. An example

is an overhead line supply with earth electrodes, and the mass of earth

as a return path as shown below.

Note that only single-phase systems have been shown for simplicity.

TT Network

In TT type of earthing system, consumer employs its own local earth

connection in the premises, which is independent of any earth connection

at source side.

This type of earthing is preferred in telecommunication applications,

because this system is free of any high or low frequency noise that

comes through neutral wire connected to the equipment.

The TT method is used mostly in country areas with overhead

transmission lines.

In contrast to the TN-S system there is no metallic path from the

consumer's terminals back to the sub-station transformer secondary

windings.

Because the earth path may be of high resistance, a residual current

circuit-breaker (R.C.C.B.) is often fitted so that if a fault current

flows in the earth path then a trip disconnects the phase supply.

For protection against indirect contact in domestic premises, every

socket outlet requires an RCCB with a maximum rated current of 30mA.

-----------=======--------

– About “

TT

” :

Also, it’s better to add :

– As we can use many independent

Earthing

points at consumers side only, this system is approximately used all

around the world in LV

Distribution Networks to supply Housings and buildings.

|

--------===============-----------

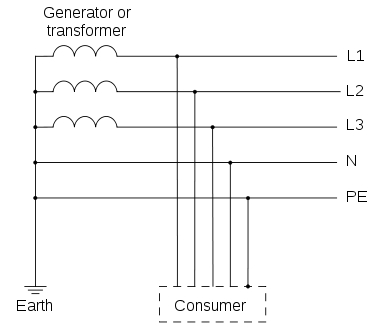

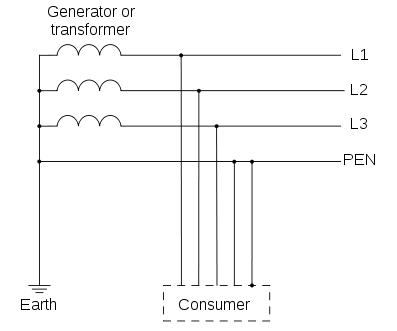

In TN type of earthing system, one of the points of the

source side (Generator or Transformer) is connected to earth. This point

is usually the star point in a three phase system. The body of the

connected electrical device is connected to earth via this earth point

on the source side. See fig. below which depicts this:

|

----------===========--------------

|

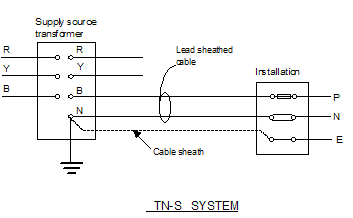

TN-S SYSTEM:

A TN-S system has the supply source directly connected

to earth, the installation metalwork connected to the neutral of the

supply source via the lead sheath of the supply cable, and the neutral

and protective conductors throughout the whole system performing

separate functions.

The resistance around the loop P-B-N-E should be no more than 0.8 ohms.

---------------============-------------

The TN-S system of wiring uses the incoming cable

sheath as the earth return path and the phase and neutral have separate

conductors. The neutral is then connected to earth back at the

transformer sub-station.

Remember in TN-S, the T stands for earth (terre), N for neutral and S

denotes that the protective (earth) and neutral conductors are separate.

|

--------=========---------

TN-C: In this, there is a combined conductor called PEN (Protective

Earth-Neutral) which is connected to earth at the source.

– About “

TN-C

” :

The following remark should be also mentioned :

– If the supply of a load is “ 3Ph + N ” and we will use only “ 1 cable

of PEN ” between the network and that load, the connection of PEN should

be done as follow “ the PEN cable should be firstly connected to the

earth point at Load, then to the neutral point ”.

|

--------==========---------

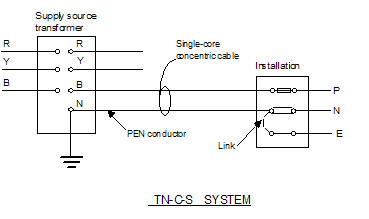

| TN-C-S SYSTEM:

A TN-C-S system is as the TN-S but the supply cable sheath is also

the neutral, i.e. it forms a combined earth/neutral conductor known as a

PEN (protective earthed neutral) conductor.

The installation earth and neutral are separate conductors.

This system is also known as PME (protective multiple earthing).

The resistance around the P-B-N-N loop should be less than 0.35 ohms.

--------------=============------------

TN-C-S: In this type of earthing, part of the system uses a combined PEN

conductor for earthing, whereas for remaining part of the system uses

separate conductor for PE and N.

Usually, the combined PEN conductor is used near the source of the

system.

------------========------------

The TN-C-S system has only two conductors in the incoming cable, one

phase and the other neutral. The earth is linked to the neutral at the

consumer unit. The neutral therefore is really a combined earth/neutral

conductor hence the name PME(Protective Multiple Earthing).

------------==============-------

– About “

TN-C-S

” :

It’s mentioned that “ Usually, the combined PEN conductor is used near

the source of the system ”, but it’s better to say :

1- For the big networks where the installed power is big or too big, we

use TN-C

at the 1st and maybe also at the 2nd levels of the network, then we use

TN-S.

2- By this way we can decrease the installation’s costs for these 2

levels.

3- We can’t never ever use firstly “

TN-S

” then “ TN-C

”.

|

---------------================---------------

Country Specific Earthing Standards thanks to or copy this trackback: http://engineering.electrical-equipment.org/iec-standard/types-of-earthing-as-per-iec-standards.html/trackback

from your own site.

| UK |

– Uses Protective Multiple Earthing (PME) –

which is a form of TN-C-S type of earthing |

| Australia / New Zealand |

– Also uses TN-C-S type of earthing know as

Multiple Earth Neutral (MEN) system |

| USA / Canada |

Uses TN-C for the feed from Transformer but

uses TN-C-S within the structure at customer premises |

| France / Japan / Denmark |

Uses TT type of earthing and customer must

make its own arrangement for its own earthing connection |

-----------===========------------

Points

to consider in BS 7671 regulations:

Earth

electrodes:

BS 7671 lists a wide range of earth electrodes

recognised by wiring regulations, including earth rods, earth plates and

underground structural metalwork.

The single most importance deciding factor in

which type of electrode to use is resistance capacity of the soil in the

ground.

Ideally it should virgin, undisturbed ground, and the effects

of soil drying, freezing, and the potential for corrosion, should also be

considered, with tests carried out in the worst weather conditions.

Sizing of Circuit Protective Conductors

Several factors must be considered when working out the required size of

circuit protective conductor. A minimum cross–sectional area of 2.5mm2

copper is necessary for any separate circuit protective conductor, meaning

one which is not part of a cable or created by/contained inside a wiring

enclosure.

Earthing Conductors:

Earthing conductors defined by BS 7671 as a protective conductor connecting

the main earthing terminal of an installation to an earth electrode must be

sized appropriately, especially if partially buried. They must be made from

suitable material and protected against corrosion and mechanical damage. The

appropriate size is determined in the same way as for a circuit protective

conductor, except for with buried earthing conductors, in which case check

BS 7671 for further guidelines. In addition, earthing conductors for a TN–C–S

supply should not be smaller than the main bonding conductors.

Special Locations:

These are locations where extra precautions need to be taken. For

example PMEs cannot be used for caravans or boats as the combined neutral

and protective conductor is not allowed to be connected electrically to any

metalwork in them, whilst a TT system is recommended for hazardous areas

such as petrol stations, and should be accompanied by the supply of a

separate electrode and circuit breaker such as an RCD, in order to ensure

that the earthing in the petrol filling area and the PMP earth of the

distribution network are separated.

|

| |

--------------------------------=======================------------------------

|